NAVE HEATING

Anyone who has been to St Saviour's through the winter months will know how ineffective the gas heating system

was in trying to heat such a vast space. Installed just over 30 years ago with a gas supply introduced to the church for this sole purpose, the gas heaters replaced unsightly electric units that had been mounted at the top of the pillars in the nave in the late 1970s. It's hard to imagine the system ever lived up to expectations: to heat the building sufficiently for Sunday, the heating had to be on from Thursday and most of that heat escaped on a Saturday night with the church being used for concert hires. Despite valiant attempts to keep the system going, the remaining heaters were inspected, condemned and the gas supply capped off in January 2024. After a year of consultations with various contractors and heating engineers as well as our Diocesan Net Zero Carbon Officer and MDP Architects, the PCC opted for an electric scheme which honours our commitment to sustainable development as well as effectively heating the people rather than the beautiful yet vast space that is St Saviour's!

This first phase is an ambitious step towards providing an efficient low-carbon heating solution for the whole building,

aiming to provide a warm zone for a congregation or audience. Additional phases are likely to follow,

based on the ongoing evaluation of this first phase.

_edited.jpg)

The central section of the nave, seating approximately 100, will be covered by an additional heated layer, laid over the original Victorian wooden parquet blocks. Edged with a hard wood bevelled surround, the cabling has been laid in the underground flue system for the initial coke-fired boilers (effectively horizontal chimneys) and connected to the newly enhanced power supply.

In addition to the vapour barrier,

there is a liftable inspection section above the central grating leading to the underground Victorian flues.

There are also humidity sensors linked by wifi to a monitoring system ensuring there is no build up of moisture that may risk damage to the original wooden flooring, or increase the humidity in the building that would have adverse effects on the architecture and pipe organ.

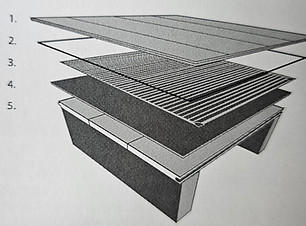

The heated floor comprises of four different layers laid on top of the existing wooden blocks (5).

A thermal insulation sheet to deflect the heat upwards (4), a carbon heating film (3), a polyester vapour barrier (2), and a wooden floor base, with a durable vinyl parquet tiles added to finish (1).

Extra effort and expense has gone into replicating the parquet pattern as closely as possible, which will be obscured by the new flooring. By choosing a slightly lighter colour a helpful visual distinction is made.

Rather than using cheaper veneer panels, each vinyl parquet tile is individually laid to replicate the pattern as close to the original as possible - allowing for the discrepancy between modern metric and Victorian imperial measurements!

The carbon heating film is manufactured by Flexel and emits radiant heat (infrared heat) to warm the objects in the room, rather than the space/air. This creates a comfortable, even heat throughout the area and also reduces drafts.

Flexel electric underfloor heating is highly efficient, low-cost, damage tolerant and proven to be thermally efficient.

In granting the necessary legal permissions for the proposed scheme,

the Diocesan Chancellor welcomed the initiative and praised St Saviour's Parochial Church Council for

its 'level of thought, creativity and commitment to net zero thinking'.

In recognition of this, a grant of £10,000 has been made by the Diocese of St Albans, and the remaining costs will be met from PCC funds - largely from the income of our most recent

So a great big 'THANK YOU' to everyone who supported us and

helped make the heating happen!